Since the time when, in 2011, renowned designer Nendo presented a clear acrylic table with a wooden pattern, scientists made several steps toward real transparent wood and more sustainable architectures.

Transparent table by Nendo | Photography: Masayuki Hayashi

Transparent wood is considered a promising structural and light management material for energy efficient engineering applications and wooden architecture.

According to experts, more sustainable building materials will be a determining factor in reducing the emissions generated by buildings and infrastructure in cities by 44% by 2050.

Transparent wood for the first time was created in the year 1992 by a German researcher Siegfried Fink. But it was not until between 2015 and 2016 when the two professors, Professor Lars Berglund from Swedish KTH University and Professor Liang Bing Hu from the University of Maryland, developed a method to eliminate colour, some of the chemicals from small wood samples and added polymers to make it transparent.

Known as transparent wood, this is a multi-purpose material that can provide significant benefits for sustainability in the building industry and the environment itself.

Lars Berglund, professor at the Wallenberg Wood Science Centre in KTH, says that while optically transparent wood had been developed in microscopic samples during the study of wood anatomy, the new KTH project introduces a way to use the material on a large scale.

To produce it, the team headed by the researcher, Céline Montanari, has removed the lignin from the wood, the main light-absorbing component in wood, and then add acrylic components to it during a subsequent phase. [source]

The result was a new frosted and almost transparent material, strong enough to be used in construction.

During the heating process, optical transmittance increases by 6% and reaches 68% for 1.5 mm thick see-through wood thermal energy storage.

Source: Xia et al., Sci. Adv. 2021; 7 : eabd7342 27 January 2021

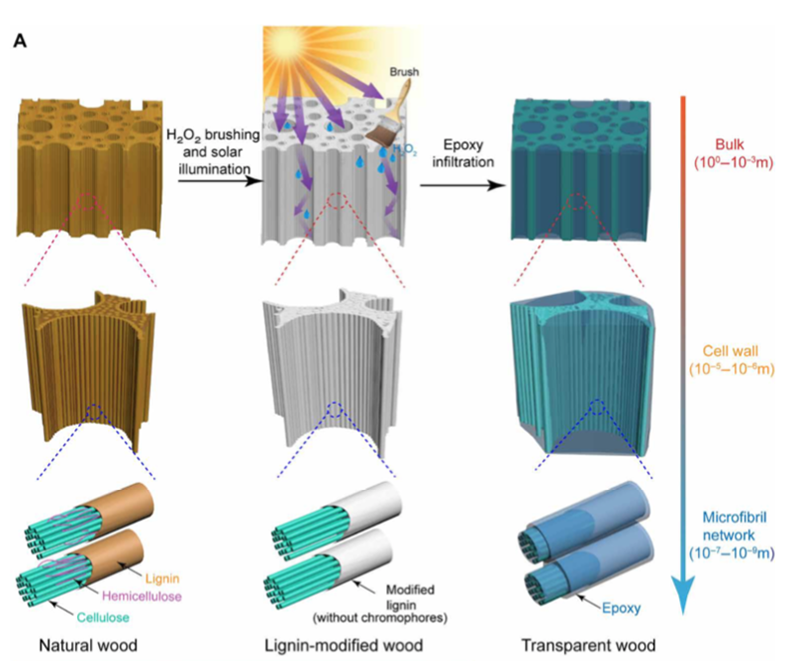

Nowadays, a team of researchers at the University of Maryland has found a new way to make wood completely transparent which they believe to be better than the previous techniques.

They made wood transparent by making it a material that can be crossed by light almost like glass, but more resistant and with better insulating properties, by modifying the structure of the wood's lignin and using a chemical brushing approach assisted by the sun.

This method preserves most of the lignin to act as a binder, providing a robust wood scaffold for polymer infiltration while greatly reducing the chemical and energy consumption as well as processing time.

Source: Xia et al., Sci. Adv. 2021; 7 : eabd7342 27 January 2021

The obtained transparent wood (~1mm in thickness) demonstrates a high transmittance (>90%), high haze (>60%), and excellent light-guiding effect over visible wavelength.

Furthermore, it is possible to achieve diverse patterns directly on wood surfaces using this approach. Combining its efficient, patternable, and scalable production, this transparent wood is a promising candidate for applications in energy-efficient buildings and sustainable architectures.

Maryland Technology Enterprise Institute (Mtech) has assisted some innovative startups from various industries that have the potential to be the business success story.

One of these startups is InventWood, an advanced materials company created to commercialize the cellulose-based innovations of Liangbing Hu, Herbert Rabin Distinguished Professor in the Department of Materials Science and Engineering and Director, Center for Materials Innovation.

Hu's research team discovered how to alter the chemistry and structure of commonly used wood to create a number of impressive discoveries such as wood that is stronger and lighter than steel—and even bulletproof.

The company plans to develop a portfolio of various wood-based materials for products such as strong and tough wood for lightweight vehicles, see-through wood for windows and skylights, thermally insulative wood for higher building efficiency, clear paper for consumer electronics, and even green, wood-based batteries.

To address these processing issues as well as obtain desirable optical and mechanical properties, recent studies have begun to optimize the preparation of transparent wood by controlling the degree of delignification.

Many different types of wood, from balsa to oak, can be made transparent, and it doesn't matter if it is cut along the grain or against it. If the transparent wood is made a little thicker, it would be strong enough to become part of the structure of a building, so there could be entire transparent wooden walls.

Although these partial delignification methods reduce the processing time and improve the mechanical characteristics of transparent wood, they require toxic chemicals that are difficult to dispose, as well as large solution volumes to enable complete immersion of the materials. In addition, further simplifying the reaction process with even shorter processing time would improve the scalability and efficiency of transparent wood production.

While this technology has yet to be scaled up to industrial levels, the researchers say it has great potential as a new building material.

Applications of transparent wood

- transparent wood roofs can be designed to certain buildings for providing uniform and comfortable illumination

- transparent wood panels for lower thermal conductivity, better impact strength, and lower density as compared to glass

- transparent structural material for some of the photovoltaic devices such as electrochromic devices and solar cells

- transparent wood façades in cases where there is a requirement for sunlight to illuminate the interior

Are you ready for your future see-through wooden building?